3D printed digital sundial

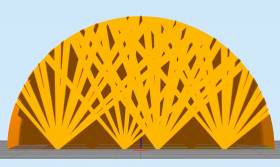

Last year a clever guy named Julien Coyne posted his design for a digital sundial (Figure 1). As the sun moves across the sky, the digits representing 24-hour time are displayed in the shadow of the gnomon (the angled arm that traditional sundials have).

|

| Figure 1. The gnomon has intricate pathways for sunlight to pass through when the sun angle is just right. |

This was not the first digital sundial. The first one was a fiber optic device developed in 1984 by Steve Hines and patented in 1988 (Figure 2). In the following decade other designs were developed and patented in 1996 and 1997. These were simpler devices which directly blocked the sunlight except for the rays illuminating the digits in the time display. One of these is still offered for sale as an indoor (e.g., window mounted) time display (Figure 3). I have always wanted one of these, but they cost $129.00, so I have been satisfied with an old fashioned gnomon stuck in the ground so it points at the north star and is surrounded by an arc of carefully placed rocks.

|

| Figure 2. Steve Hines patented this digital sundial in 1988. As the sun moves, light from an entrance slit enters fiber optic strands which guide the light to the proper plexiglas segment of a digit. |

|

| Figure 3. This beautifully made digital sundial was developed in the 1990s and is sold by one of the developers -- Daniel Scharstein of Middlebury College. |

The expense of the commercial digital sundial is due to the great precision required to manufacture it. Tiny masks block the sunlight except when the angle is just right, and these masks must be aligned perfectly.

Julien Coyne understood that a parametric CAD (computer aided design) program could create the intricate 3D model of the gnomon with a few lines of code repeated for each desired sun angle and for each “pixel” defining the projected digits. The resulting object would be difficult to manufacture with traditional methods, but would be quite simple to make with a 3D printer. This sundial is one of the more elegant examples of a complex problem that has waited decades to be solved by 3D printing.

In October, 2015 Coyne posted an elaborate and entertaining video about his sundial and also made the design files freely available. The video has been watched 426,000 times and the printing files have been downloaded 80,000 times from Thingiverse. The other patents from the 1990s have both lapsed (the owners stopped making fee payments) and might not have covered Coyne’s approach anyway. Coyne sells his sundials on Etsy (it takes him 30 hours to print each one), but the primary impact of his work is the thousands of people who can print their own. The great mystery of Coyne’s contribution is that the sundial video was his first real post at his Mojoptix website, and there has not been another one since. Maybe he’s just too busy printing gnomons.

I made a timelapse video of the display of one of the sundials I printed. I used a Canon PowerShot the first time but the automatic focus made the video jerky. So I used a Canon EOS M with manual focus and that worked better. I took a photo every six seconds using the intervalometer feature in the firmware enhancement Magic Lantern. The silent video below also has the CAD model being manipulated in the slicing program Simplify 3D.

Video has no audio.

Digital sundials don’t change the digits every minute, and to make the printing manageable, Coyne limited the time increment to 20 minutes. He also limited the operating span to the six hours between 10:00 and 16:00 (10 AM to 4 PM). These were good decisions because the maze of light paths through his gnomon requires a structure about as intricate as home 3D printers can handle. When I printed mine I did not use the finer layer thickness that Coyne recommends and the printing took about half the time he reported. The projected time display of mine has some artifacts which might be due to my lower resolution printing.

The sundial needs a supporting base, and Coyne’s sundial is designed to screw onto the top of a jelly jar which you can fill with rocks or coins so the whole thing won’t tip over. Unfortunately, Coyne is French, and his design requires a French jelly jar. This was discouraging until I found a box of dusty jars in the garage and was astounded to see French label on a few of them. The fact that in a few minutes, without leaving the house, I was holding French jelly jars prevented me from complaining about life for at least a day and a half. As it happens, Bonne Maman is a common brand of imported jelly distributed in the US, and I was soon buying new French jars filled with really wonderful French jelly.

A fine French jelly jar full of stones makes a sturdy base for the gnomon. Coins are even better.

The best imported jelly jars make the best sundial bases.